In automotive repair, good lighting directly affects work efficiency and operational safety. Headlamps, magnetic lights, and work lights are three mainstream solutions, each with its own applicable scenarios, advantages, and disadvantages. Here is a detailed comparison and purchasing suggestions:

I. Core Requirement Analysis

- Irradiation angle: Narrow spaces such as the chassis and engine compartment require multi-angle lighting.

- Brightness requirement: Precision maintenance (such as circuit detection) requires high color rendering (CRI > 90).

- Portability: Hands need to be free when working alone.

- Power supply mode: Duration of continuous operation and convenience of charging.

II. Horizontal Comparison of Three Lighting Tools

- Headlamp (Head-mounted LED Light)

Advantages:

- 100% hands-free operation: Automatically aligns with the work area as the head turns, ideal for complex solo operations (such as gearbox disassembly and assembly)

- Precise focusing: High-quality models are equipped with dual spot and flood light sources, with a range of up to 100 meters

- Lightweight: Weighing less than 100g, no burden for long-term wear

Disadvantages:

- Limited illumination range: Cannot illuminate large areas simultaneously (such as the entire vehicle chassis)

- Heat dissipation issues: May heat up after 30 minutes of continuous use in high-brightness mode

Key parameters:

- Brightness: 800-1500 lumens

- Battery life: 2-4 hours in high-brightness mode (replaceable battery models are better)

- Water resistance: IPX4 splash-proof

Suitable scenarios:

- Internal inspection of engine compartments, wire harness troubleshooting, nighttime emergency rescue

- Magnetic Light (Magnetically Attached LED Light)

Advantages:

- Arbitrary positioning: Strong magnetic base can attach to vehicle frames, lifts, and tool cabinets (load capacity ≥ 5kg)

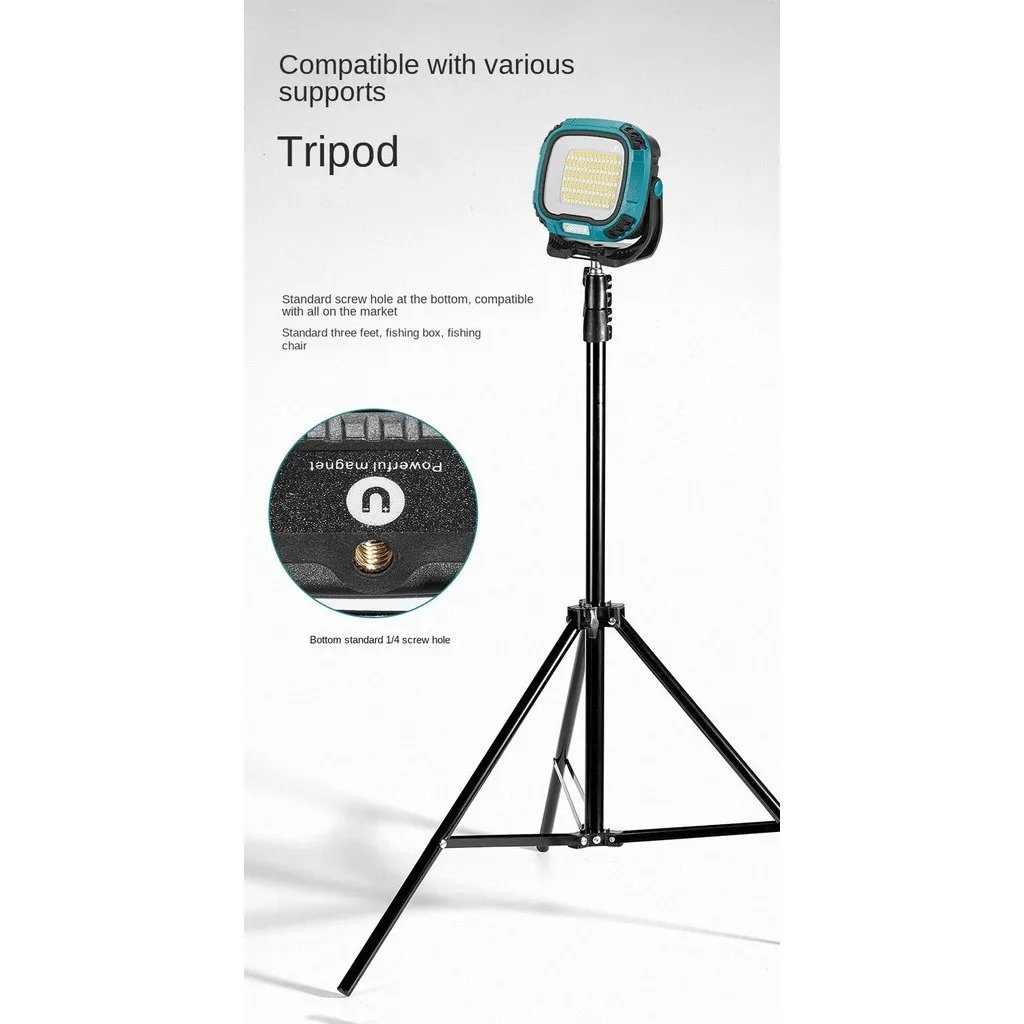

- Multi-angle adjustment: Lamp head usually supports 360° rotation

- Drop resistance: Military-grade casing can withstand 2-meter drops

Disadvantages:

- Dependence on metal surfaces: Plastic components (such as bumpers) require matching with extended magnetic plates

- Moderate brightness: Generally 500-800 lumens, not suitable for extra-large spaces

Key parameters:

- Magnetic force: ≥15N suction (can be attached upside down to the vehicle bottom)

- Battery life: 6-8 hours in medium-brightness mode (18650 batteries replaceable)

- Temperature range: Normal operation from -20℃ to 50℃

Suitable scenarios:

- Wheel disassembly and assembly, chassis inspection, sheet metal work

- Work Light (Floor/Stand-type LED Light)

Advantages:

- Super large coverage: Bar-shaped lights can illuminate the entire work station (3000 lumens+)

- Professional-grade color rendering: RA > 95 to restore true colors and distinguish color differences (such as oil fluid status)

- Stable power supply: Plug-in type/large-capacity battery (20000mAh+) supports 10 hours of full load operation

Disadvantages:

- Inconvenient to move: Large size (length often > 50cm), not suitable for field operations

- Shadow interference: Single light source is easily blocked by the vehicle body, creating blind spots

Key parameters:

- Color temperature: 5000K neutral white light (balances brightness and comfort)

- Protection level: IP54 dust and water resistance

- Special functions: Emergency power bank/voltage display

Suitable scenarios:

- Vehicle sheet metal painting, in-depth disassembly, multi-person collaborative work

III. Pitfall Avoidance Guide

- Headlamp: Avoid choosing cheap models with non-adjustable angles (fixed illumination direction can easily cause dizziness)

- Magnetic light: Models with insufficient magnetic force (<10N) may easily fall off due to vibration under the vehicle

- Work light: For plug-in types, confirm that the wire length is ≥3 meters (common requirement for lift workstations)

Solutions for special needs:

- Damage inspection: Choose magnetic lights with UV ultraviolet lamp heads

- Extreme environments: ATEX-certified explosion-proof headlamps

VI. Maintenance Tips

- Battery maintenance: Store lithium battery equipment with 30%-80% charge (full charge storage reduces lifespan)

- Cleaning: Wipe oil stains on the lamp bead surface with alcohol pads (especially after sheet metal work)

- Upgrade: Magnetic lights can be equipped with flexible light strips to expand the illumination range

Flexible matching according to work scenarios can improve maintenance efficiency by more than 30%. It is recommended to prioritize the combination of headlamp + magnetic light, and supplement with work lights as needed.